CNC high-speed gantry machining centers are high-precision equipment suitable for processing large and complex parts, with their advantages mainly reflected in the following aspects:Wide processing rangeEquipped with a l...

READ MORELM-1311 4 Axis CNC Gantry Engraving Machine

Application scenarios and scope of application

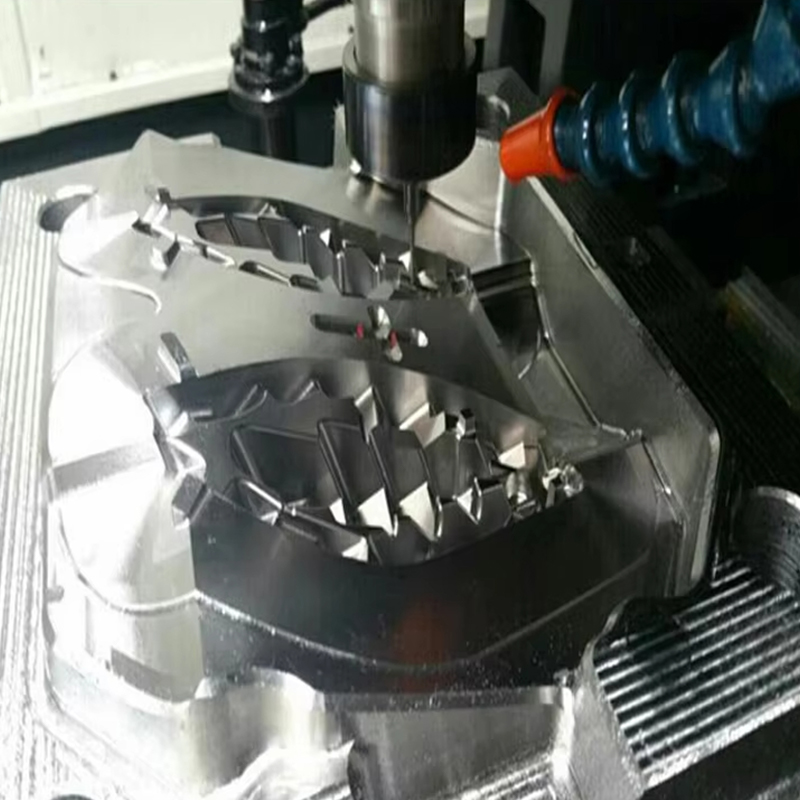

The LM-1311 is used in mold making, aerospace components, and artistic engraving. It processes materials such as aluminum alloys, plastics, and composite boards. The rotary axis facilitates tasks like helical milling, cylindrical embossing, and irregular contouring.

Description

Contact us

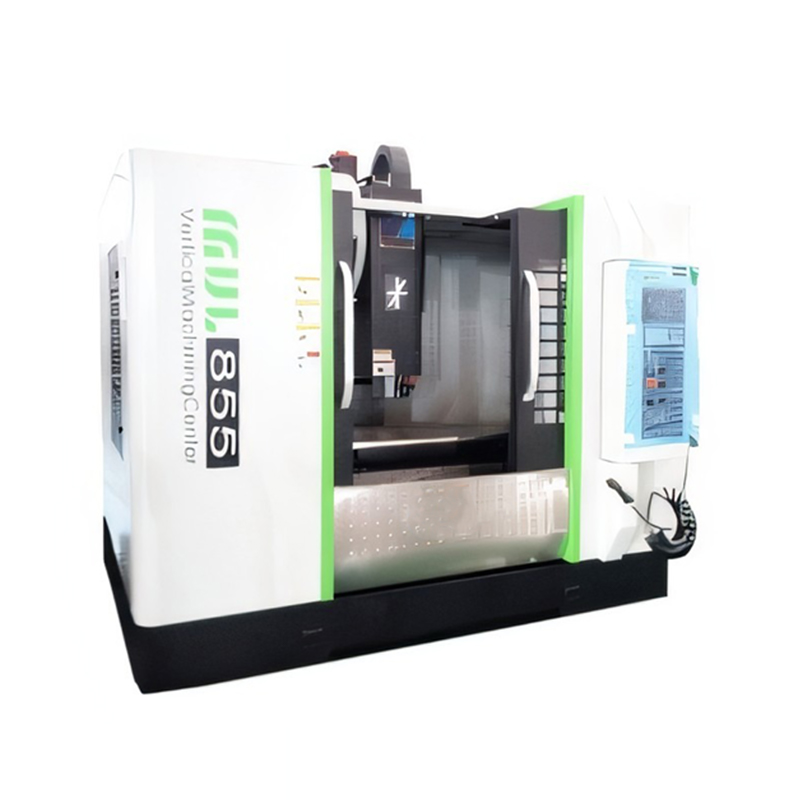

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, incorporating a rigid gantry structure and a 4-axis rotary mechanism. It supports operations on complex surfaces and cylindrical workpieces, suitable for industrial production and custom fabrication.

Constructed with a heavy-duty frame and precision ball screws, the LM-1311 ensures stable performance during prolonged operation. The machine integrates a 4th-axis rotary unit, enabling continuous engraving and milling on non-planar geometries. Its modular spindle assembly accommodates various tooling requirements, while the servo-driven axes provide consistent motion control.

Product Features/Advantages

Gantry Design: Enhances rigidity for reduced vibration during high-load machining.

4-Axis Capability: Supports simultaneous control of XYZ linear axes and one rotary axis.

Adaptive Tooling: Compatible with multiple spindle configurations for diverse material removal rates.

User Interface: Streamlined CNC system with offline programming support for efficient workflow integration.

The LM-1311 is engineered to meet the demands of multi-axis machining, balancing structural durability with operational flexibility.

Specification

| model | LM-1090 (Light gantry milling) | LM-1311 (Light gantry milling) | LM1609 (Light gantry milling) | LM-1613 (Light gantry milling) | LM-1813 (Light gantry milling) |

| Workbench area (length × width) (mm) | 1000×750 | 1060×800 | 1300×1000 | 1600×800 | 1800×1200 |

| T-slot number (mm) | 5-14 | 5-18 | 5-18 | 7-18 | 7-22 |

| Spindle speed (r/min) | 3000~ 24000/21000 | 3000 - 24000/18000 | 3000 - 24000/18000 | 8000/15000 | 8000/15000 |

| Spindle output power (KW) | 3.2 | 3.2/4 | 4/5.5 | 4/5.5/7.5 | 15 |

| Spindle (Tool diameter range circumference) | φ3 - φ12 | φ3 - φ12 | φ3 - φ12 | φ3 - φ12/16 | φ150 BT40 servo |

| Three-axis travel (X*Y*Z axis) (mm) | Three-axis travel (X*Y*Z axis) (mm) | 450×400×200 | 500×500×250 | 600 × 600 ×250 | 1300×1800×700 |

| Minimum distance from spindle to table (mm) | 1300×1800×700 | Minimum distance from spindle to table (mm) | 30 | 60 | 150 |

| Gantry passage height (mm) | 150 | 150 | Gantry passage height (mm) | 230 | 850 |

We can provide you with a satisfactory plan!

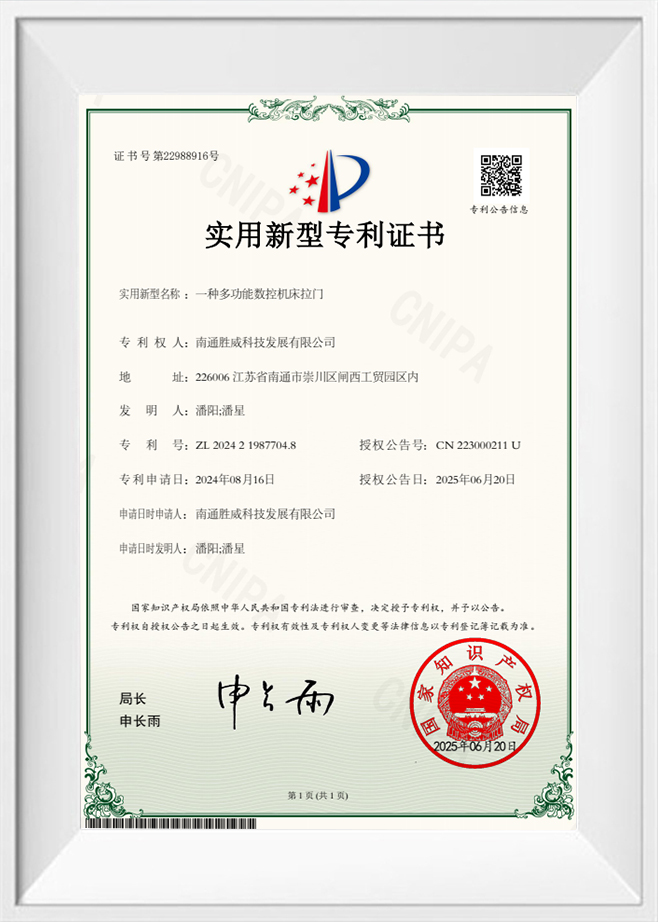

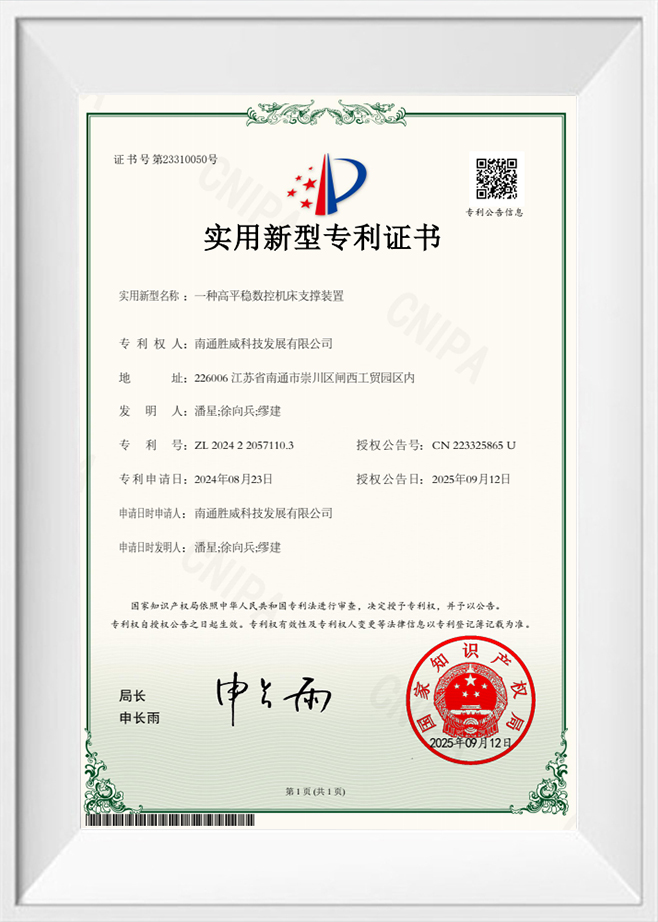

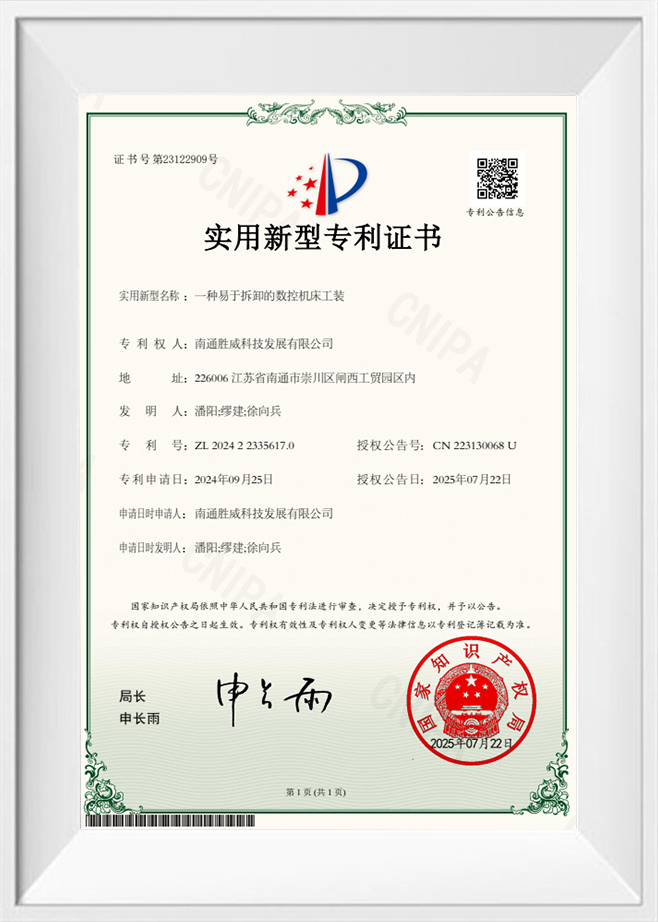

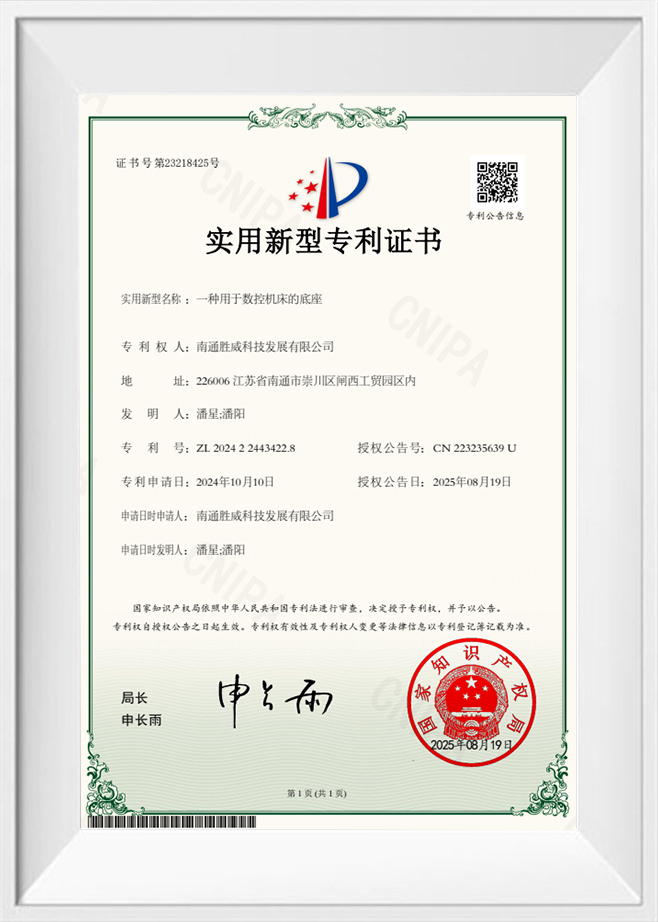

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

-

Nantong Sunway Science and Technology Development Co., Ltd. is a comprehensive enterprise specializing in the R&D, manufacturing, and sales of numerical control equipment. Located in Nantong, Jiangsu Province, it enj...

READ MORE -

Graphite engraving and milling machines are CNC equipment specifically designed for processing graphite materials, with their advantages mainly reflected in the following aspects:Targeted adaptation to graphite propertie...

READ MORE

русский

русский Español

Español