CNC high-speed gantry machining centers are high-precision equipment suitable for processing large and complex parts, with their advantages mainly reflected in the following aspects:Wide processing rangeEquipped with a l...

READ MORECNC-OX540 3 Axis CNC EDM Die Sinking Machine

Application scenarios and scope of application

Primary uses include precision mold and die fabrication, aerospace component machining, and specialized tool production. The machine processes materials such as hardened tool steels, carbides, and heat-resistant alloys, accommodating applications where conventional cutting methods are impractical.

Description

Contact us

The CNC-OX540 3-Axis CNC EDM die sinking machine is engineered for controlled electrical discharge machining of conductive metals. Its three-axis CNC system provides precise movement control, making it suitable for applications demanding intricate shaping and fine surface quality. The machine is built for durability and repeatability in industrial environments.

Featuring a robust construction and optimized spark erosion technology, the CNC-OX540 delivers consistent machining performance. The system includes real-time monitoring and adaptive discharge adjustment to maintain stable operation. Its programmable settings allow for efficient handling of complex geometries without manual intervention.

Product Features/Advantages

CNC-Controlled Axes: Ensures accurate positioning and repeatable machining paths.

Dynamic Discharge Regulation: Automatically adjusts energy output based on material and machining conditions.

Rigid Frame Design: Minimizes deflection and maintains stability during extended operation.

Integrated Process Automation: Includes automated flushing and electrode management for reduced downtime.

Expandable Functionality: Supports optional attachments for specialized operations.

Specification

| Model | OX-430 (450) | OX-540 | OX-650 | OX-850 | OX-1060 | |

| Work surface size (mm) (length × width) | mm | 700×400 | 850×500 | 900×650 | 1100×650 | 1250×800 |

| Left and right travel (X axis) | mm | 450 | 500 | 600 | 850 | 1000 |

| Front and rear travel (Y axis) | mm | 350 | 400 | 450 | 500 | 600 |

| Spindle travel (Z axis) | mm | 300 | 300 | 400 | 400 | 500 |

| The distance from the lower end of the T-slot plate to the work surface | mm | 320-620 | 370-670 | 370-770 | 500-900 | 500-1000 |

| Oil tank inner cavity dimensions (length × width × height) | mm | 1200×700×440 | 1440×800×500 | 1616×950×550 | 1800×1100×600 | 2100×1250×600 |

| Fuel tank capacity | L | 703 | 828 | 1177 | 1340 | 1960 |

| Maximum electrode weight | mm | 100 | 120 | 150 | 200 | 400 |

| Workbench load-bearing | kg | 1000 | 1800 | 2500 | 3000 | 3500 |

| Machine weight | kg | 2500 | 3300 | 3500 | 4500 | 6500 |

| Unit price | yuan | 70000 | 83000 | 92000 | 104000 | 140000 |

We can provide you with a satisfactory plan!

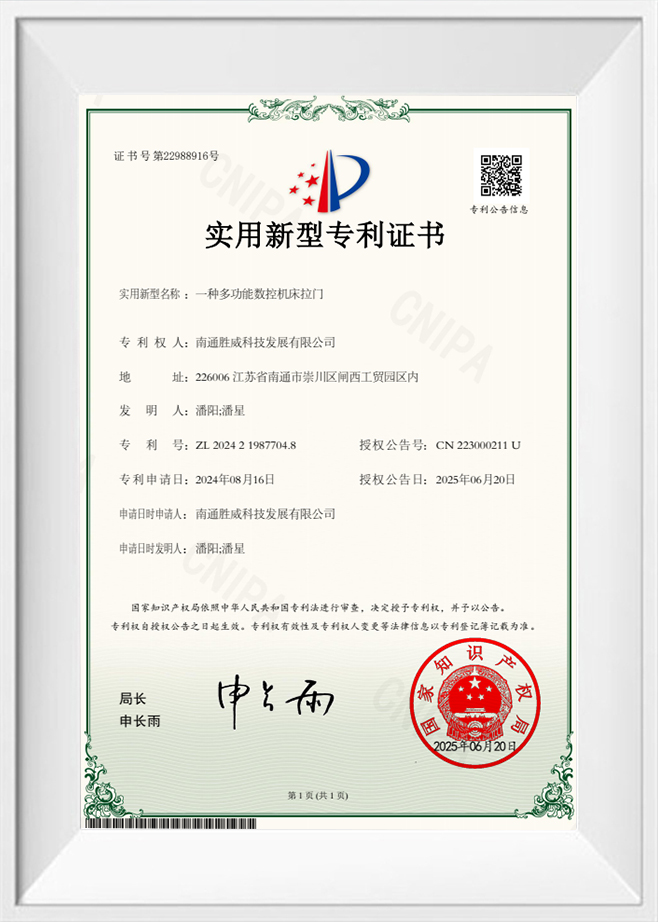

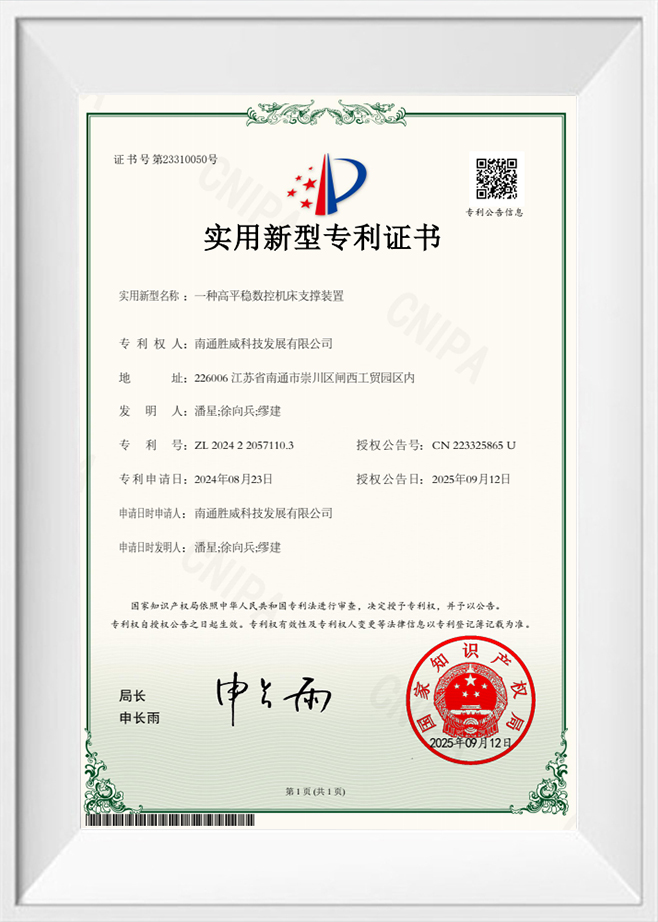

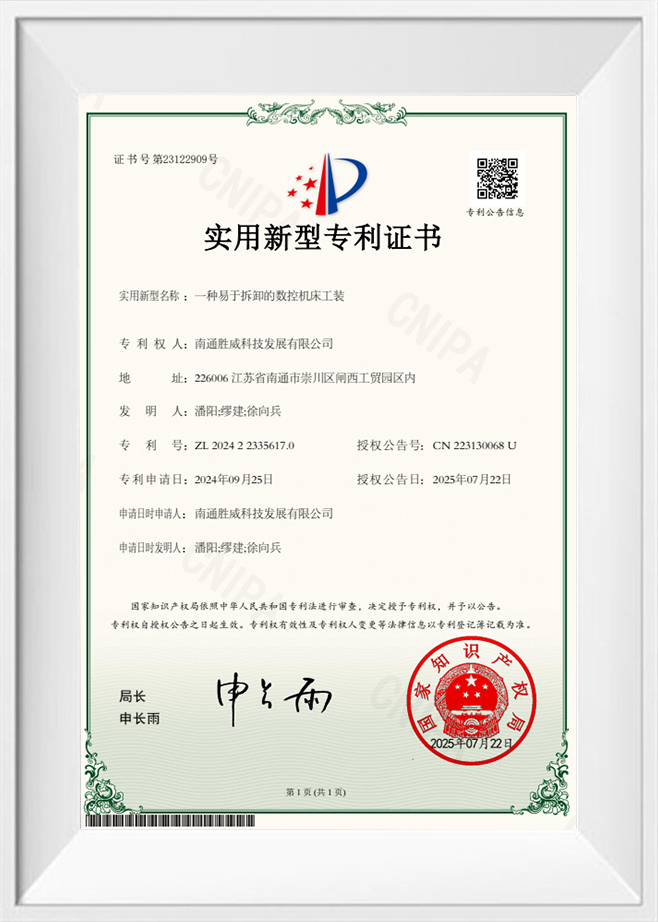

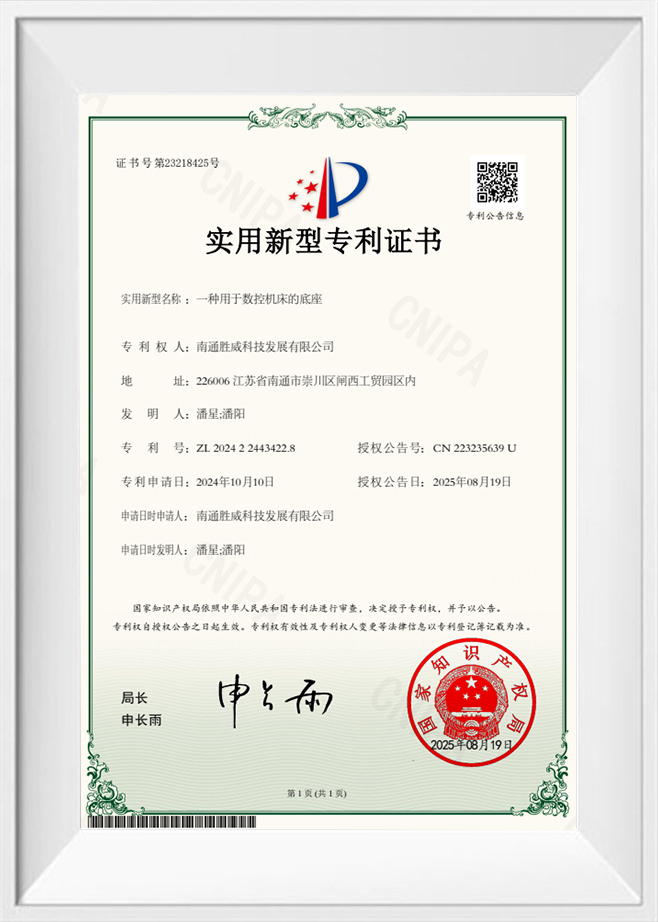

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

-

Nantong Sunway Science and Technology Development Co., Ltd. is a comprehensive enterprise specializing in the R&D, manufacturing, and sales of numerical control equipment. Located in Nantong, Jiangsu Province, it enj...

READ MORE -

Graphite engraving and milling machines are CNC equipment specifically designed for processing graphite materials, with their advantages mainly reflected in the following aspects:Targeted adaptation to graphite propertie...

READ MORE

русский

русский Español

Español