Information to be updated

Custom Graphite Engraving Milling Machine Manufacturers

1. Product Performance

(1). Whole resin sand of high-quality casting, exported to DMG company (Germany) for sixteen years continuously, and TOSHIBA in Japan, after stress relieving and precision finish, key position uses imported components and is installed according to international standards.

(2). Our three-axis precision grade high rigid line rail uses HIWIN(Taiwan) or PMI, C3 grade precision double nuts ballscrew after pre –tight eliminate the intervals between axes, increase the transmission accuracy, ensure the favorable positioning accuracy and resetting accuracy of each axis. This machine is suitable for machining complex curved surface parts in the machinery industry for its high efficiency and performance, especially for high-precision moulds. Graphite can also be processed. It has a spindle water curtain processing function, a processing liquid filtration function, a machine table, and screw protection.

(3). We use a positive displacement oil distributor, timing, and ration to supply oil to each lubrication housing, ensuring the uniformity and lubrication of each lubrication surface, and decreasing slide grind resistance effectively.

(4). X、Y、Z three axis exchange servo motor contact precision ballscrew through high precision no backlash,ballscrew and bearing use high precision and rigid like group angle contact ball bearingX、Y、Z three axis exchange servo motor contact precision ballscrew through high precision no backlash,ballscrew and bearing use high precision and rigid like group angle contact ball bearing.

(5). Repeating accuracy:0.003㎜

(6). Special measures for graphite processing

For the processing of graphite specimens, due to the high-speed processing of graphite will produce dust, affecting the machine tool and working environment.

1)Using cutting fluid, add water curtain around the high-speed spindle to protect most of the dust, and cool the graphite to prevent deformation during high-speed processing;

2)At the same time, the processing liquid is filtered and can be reused many times.

3)The key parts of the machine tool are equipped with dustproof devices, and the guide rail and screw rod of the machine tool are protected by multi-layer telescopic sheathing.

4)The overall use of surface spray, closed protective cover, and open double door structure, fully closed shell, to ensure that processing dust will not spread to the machine, supplemented by a high-power dust removal and chip collection device.

5) The machine bed and workbench will be specially treated, with acid resistance and corrosion prevention characteristics.

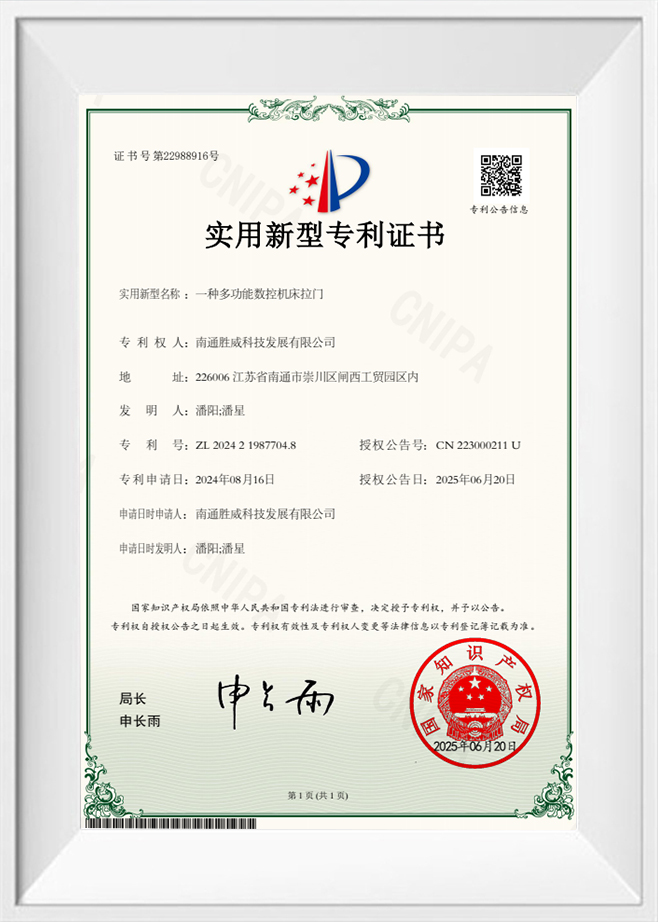

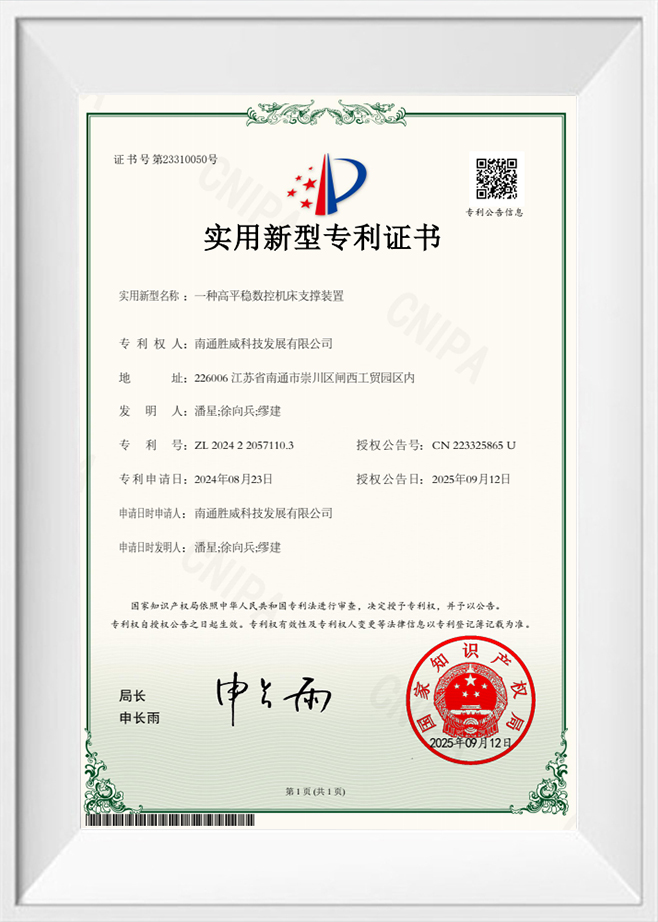

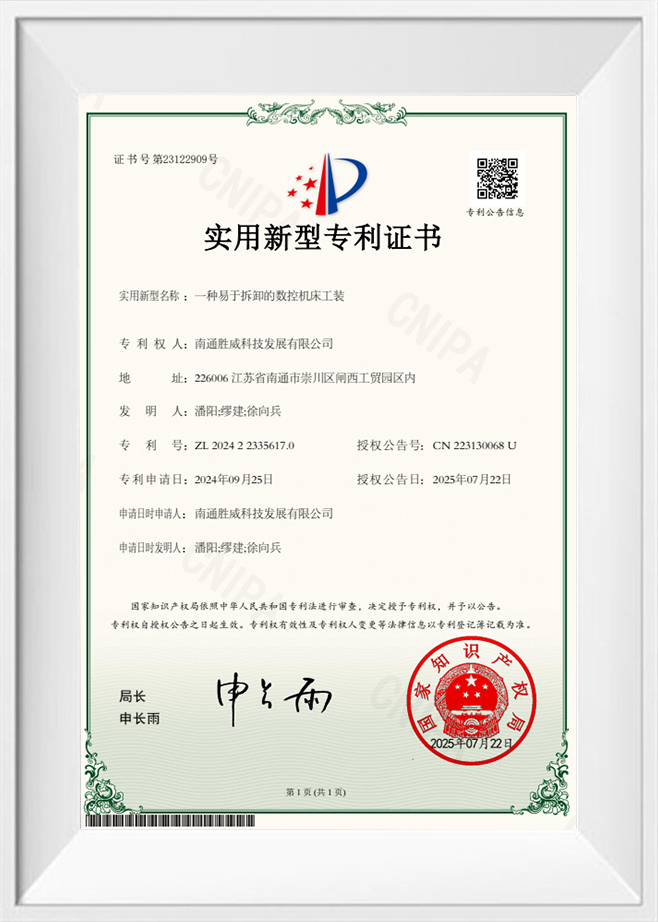

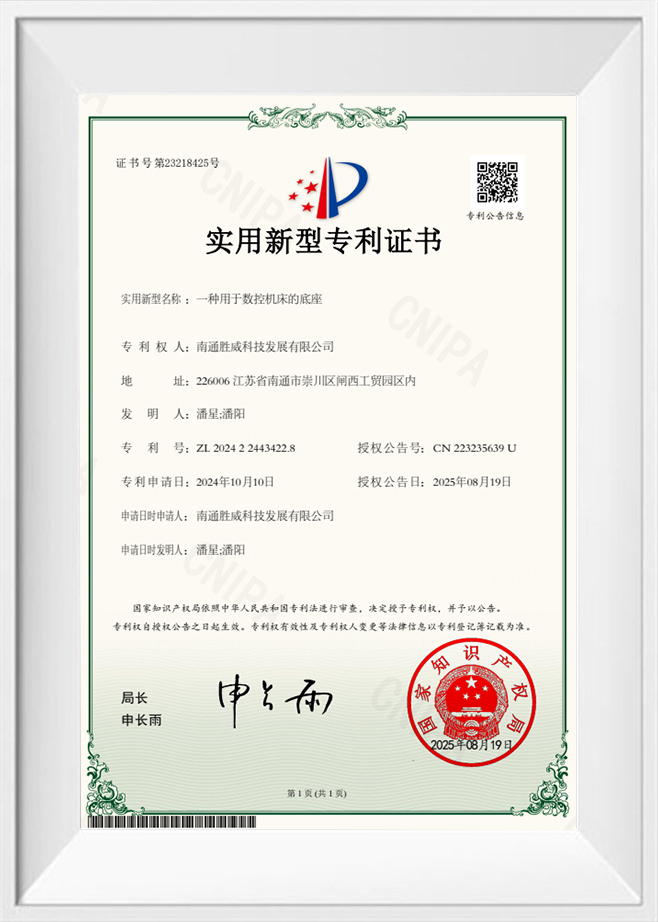

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

CNC high-speed gantry machining centers are high-precision equipment suitable for processing large and complex parts, with their advantages mainly ref...

READ MORE -

Nantong Sunway Science and Technology Development Co., Ltd. is a comprehensive enterprise specializing in the R&D, manufacturing, and sales of num...

READ MORE -

Graphite engraving and milling machines are CNC equipment specifically designed for processing graphite materials, with their advantages mainly reflec...

READ MORE

русский

русский Español

Español