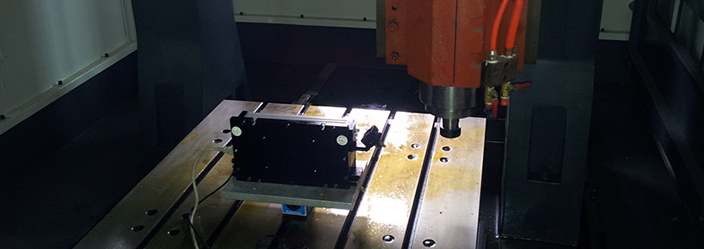

The company’s main products include several series, including CNC machining centers, EDM forming machines, high-speed milling and engraving machines, small gantry milling machines, CNC EDM machines, and frame-type milling and engraving machines. These products are widely used in mold manufacturing, precision parts processing, hardware, automotive parts, electronics, aerospace, and other industries.

Since its establishment, Sunway has continuously invested in fundamental manufacturing and technical equipment. It has built a high-standard foundry and a large factory for structural parts processing, covering an area of approximately 10,000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, establishing independent capabilities for processing and assembly from structural parts to complete machines.

Sunway has always adhered to the business philosophy of “being honest, pursuing excellent quality, working diligently, and developing through innovation.” It places great emphasis on the outgoing product quality, strictly implements the testing process, and strives to deliver each product with stability and reliability. Thanks to stable performance and reliable service, Sunway products have won customer praise in China and have also been exported to Europe, North America, Southeast Asia, and other regions.

We believe that high-quality products stem from the steadfast accumulation of experience and expertise. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other areas, striving to become your trustworthy machinery and equipment manufacturing partner for the long term.

-

0

Annual Production (units)

-

0

Production Experience

-

0

Export Countries

-

0

Cooperative Partners

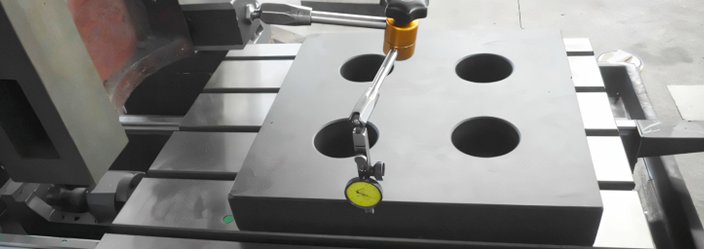

Quality is Sunway’s core commitment. From casting precision to final assembly and testing, every process strictly adheres to internal quality standards as well as international regulations. We have a professional quality inspection team responsible for incoming material inspection, process monitoring, and final machine testing to ensure the equipment’s reliability and consistent performance.

Technology-Driven Growth: Sunway’s machines are equipped with a 64-bit central processing unit and an industrial-grade PLC control platform, enabling efficient data processing and intelligent machining. The control system is compatible with multiple operating systems (such as Mitsubishi, SIEMENS, LNCSYNTEC, Weihong, etc.) and can be flexibly configured according to customer requirements to enhance operational efficiency and system compatibility.

Global Reach:Sunway products enjoy strong sales in China and are exported to more than ten countries and regions, including Europe, Southeast Asia, South America, India, and South Korea. With stable performance and high-quality service, they have been highly recognized by OEMs and SME customers.

-

2000

2000In April, the company successfully produced the uniaxial CNC EDM (Electrical Discharge Machining) series.

-

2003

2003To meet the needs of modernized production and product quality improvement, the company established its own R&D team and began to produce CNC milling machines.

-

2005

2005We started to continuously obtain multiple invention patents in terms of technology.

-

2007

2007The company developed and produced high-speed CNC engraving and milling machines as well as small CNC gantry machines, gradually forming a series. It became the first domestic factory to serialize small gantry machines.

-

2010

2010The company established product lines including uniaxial and three-axis CNC EDM forming machines, machining centers, high-speed engraving and milling machines, and small CNC gantry machines. Its products were exported to the United States, South Korea, Russia, Taiwan (China), Vietnam, the Middle East, South America, with business covering over 160 countries and regions.

-

2022

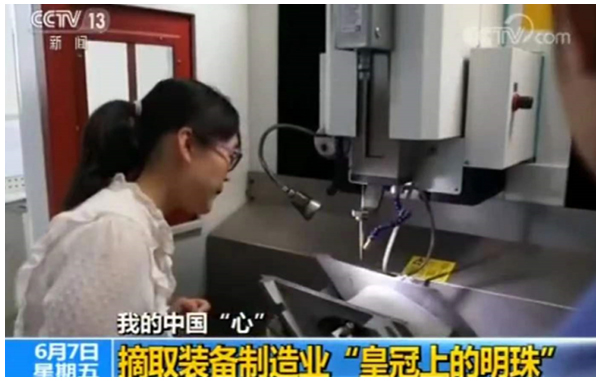

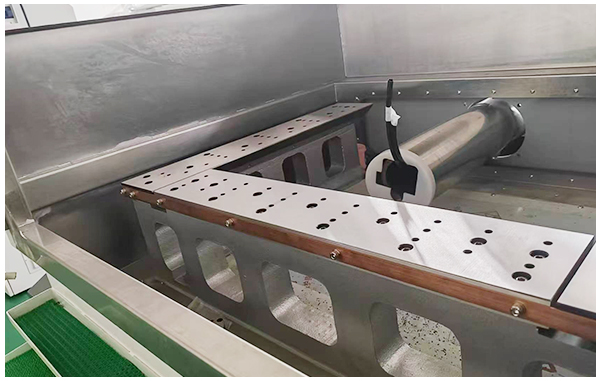

2022The slow wire cutting machine represents the top level of electric discharge wire cutting technology. It achieves ultra-high precision and high quality processing of hard conductive materials through precise electromechanical control, intelligent power technology, and fully automatic process flow. It is one of the core equipment in modern high-end manufacturing and precision engineering fields.

-

2025

2025The carrier rocket engine testing platform is the cornerstone of the aerospace industry and serves as a bridge connecting design and flight. It integrates the most advanced engineering technology and the strictest safety standards, and is an important indicator of a country's aerospace capabilities.

- 2000

- 2003

- 2005

- 2007

- 2010

- 2022

- 2025

русский

русский Español

Español